This is the Catalyst Glass factory exclusively for Lost Surfboards.

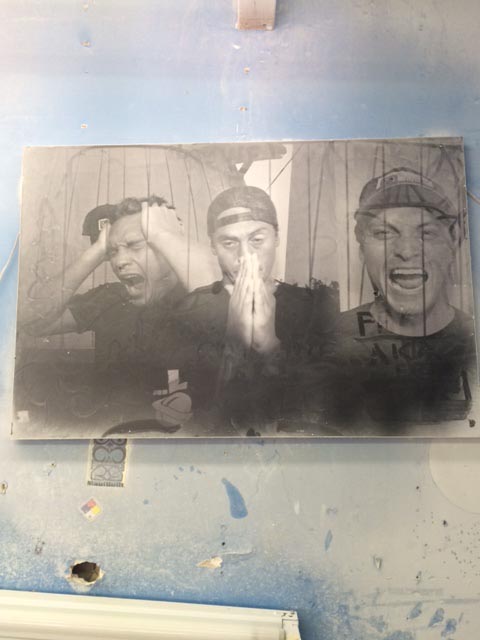

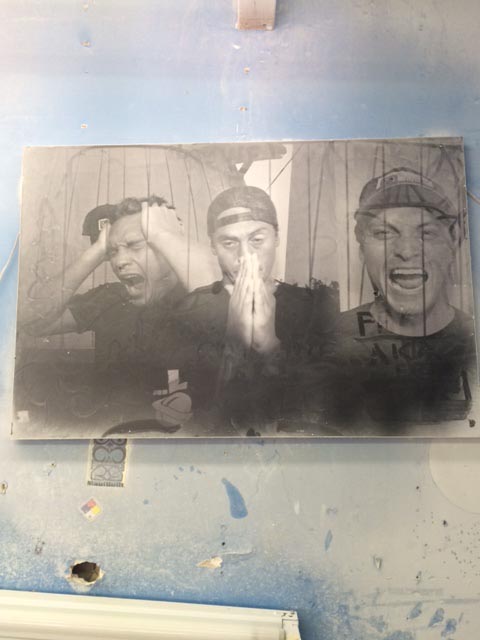

The poster has apparently been up for about 40 years.

This is a POLY board in the hot coat stage.

After wrapping it in cloth and resin, we coat it with just resin.

At that time, we work to create the necessary edges for each model, as shown here.

There is a photo of the nostalgic Gokin's Gokin Flip posted.

This technique is so difficult that it has yet to be demonstrated even in the WCT.

This is a custom-made SUB-SCORHER board. This classic model is still being ordered.

You have a lot of fans in Japan as well.

Word posters posted inside the factory.

This is the sanding room where the boards are finished.

The craftsmen must have a really hard time getting covered in resin powder in a small room.

Catalyst, the USA head shop for Lost surfboards.

There is a glass shop behind this surf shop.

Storage for the main Arctic foam used.

Each piece is custom-made to fit the model.

This is Terry Singh's room, the airbrush room.

Here, we mix colors to match the order board and color the board with an airbrush.

This is the room where we create the marks to be put on the board.

The Japanese paper used for all of the marks is produced by Love Surf at a paper company in Japan and shipped to the USA.

The quality of the paper is so good that other brands have asked us to create their logos for them.

This is a surfboard rack that can store approximately 1,500 boards.

It's quite impressive to have all of this.

Today, Love Surf's clients came from Japan and Korea, so we had to check out the factories and warehouses.

I actually gave you a tour.

This is the Catalyst Glass factory exclusively for Lost Surfboards.

The poster has apparently been up for about 40 years.

This is the Catalyst Glass factory exclusively for Lost Surfboards.

The poster has apparently been up for about 40 years.

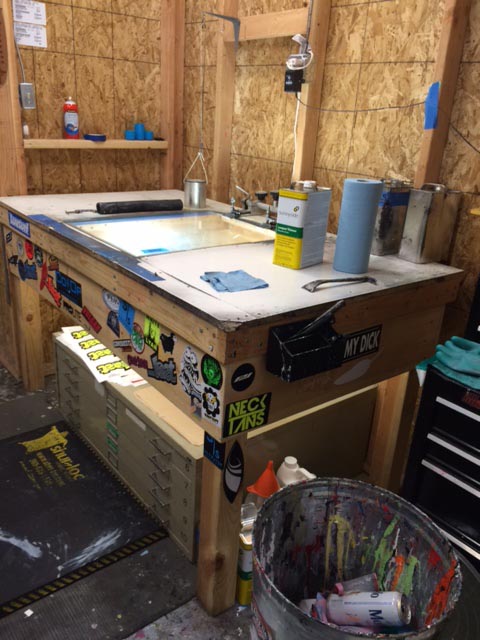

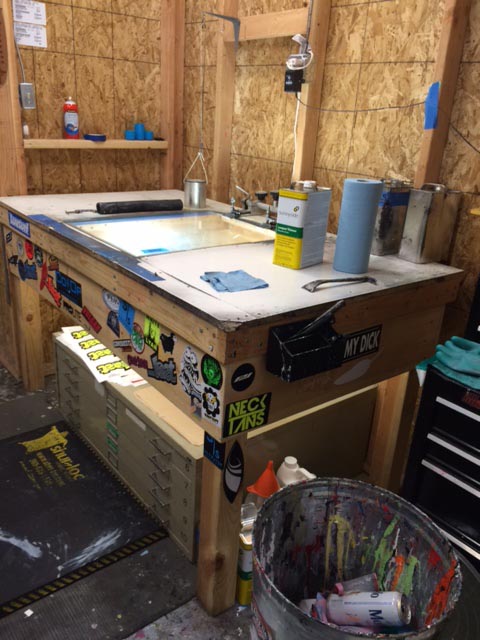

This is a POLY board in the hot coat stage.

After wrapping it in cloth and resin, we coat it with just resin.

At that time, we work to create the necessary edges for each model, as shown here.

This is a POLY board in the hot coat stage.

After wrapping it in cloth and resin, we coat it with just resin.

At that time, we work to create the necessary edges for each model, as shown here.

There is a photo of the nostalgic Gokin's Gokin Flip posted.

This technique is so difficult that it has yet to be demonstrated even in the WCT.

There is a photo of the nostalgic Gokin's Gokin Flip posted.

This technique is so difficult that it has yet to be demonstrated even in the WCT.

This is a custom-made SUB-SCORHER board. This classic model is still being ordered.

You have a lot of fans in Japan as well.

This is a custom-made SUB-SCORHER board. This classic model is still being ordered.

You have a lot of fans in Japan as well.

Word posters posted inside the factory.

Word posters posted inside the factory.

This is the sanding room where the boards are finished.

The craftsmen must have a really hard time getting covered in resin powder in a small room.

This is the sanding room where the boards are finished.

The craftsmen must have a really hard time getting covered in resin powder in a small room.

Catalyst, the USA head shop for Lost surfboards.

There is a glass shop behind this surf shop.

Catalyst, the USA head shop for Lost surfboards.

There is a glass shop behind this surf shop.

Storage for the main Arctic foam used.

Each piece is custom-made to fit the model.

Storage for the main Arctic foam used.

Each piece is custom-made to fit the model.

This is Terry Singh's room, the airbrush room.

Here, we mix colors to match the order board and color the board with an airbrush.

This is Terry Singh's room, the airbrush room.

Here, we mix colors to match the order board and color the board with an airbrush.

This is the room where we create the marks to be put on the board.

The Japanese paper used for all of the marks is produced by Love Surf at a paper company in Japan and shipped to the USA.

This is the room where we create the marks to be put on the board.

The Japanese paper used for all of the marks is produced by Love Surf at a paper company in Japan and shipped to the USA.

The quality of the paper is so good that other brands have asked us to create their logos for them.

The quality of the paper is so good that other brands have asked us to create their logos for them.

This is a surfboard rack that can store approximately 1,500 boards.

It's quite impressive to have all of this.

This is a surfboard rack that can store approximately 1,500 boards.

It's quite impressive to have all of this.

Today, Love Surf's clients came from Japan and Korea, so we had to check out the factories and warehouses.

I actually gave you a tour.

Today, Love Surf's clients came from Japan and Korea, so we had to check out the factories and warehouses.

I actually gave you a tour.