A report from the LOST Surfboard Factory in San Clemente, CA.

MAYHEM has just completed the shape of the stockboard for the "LAYZ POTATO" model "XTR FX".

He showed us the blanks that were about to be transported to the XTR factory to be vacuum glassed into "XTR FX".

As you can see when you look at the ``XTR FX,'' the production process is very time-consuming, with wooden stringers made from special, extremely thin maple wood dyed black, square carbon attached to the rails, and glassed in a vacuum bag.As a result, it is difficult to mass-produce like a POLY board, making it a rare, high-end board.

This is MAYHEM watching Chris Ward and the WCT LIVE in Europe.

Rooting for Carissa Moore's heat on a LOST Mayhem board.

Behind the desk is the board that Kolohe and Mick used.

Ward saw Mick's SUB-DRIVER board and said, "This looks good."

He said he'll peel off the sticker and try riding it tomorrow.

I started working again, designing surfboard orders using AKU software on my beloved Air Mac.

This is Mayhem. He was happy that there were a lot of custom orders for the "BEACH BUGGY" model after Taj won the WCT last week.

Luvsurf is currently holding a sale to celebrate the "BEACH BUGGY" victory, so please take advantage of this as well

Luvsurf is currently holding a sale to celebrate the "BEACH BUGGY" victory, so please take advantage of this as well .

This is Mick's SUB-DRIVER board leaning against the wall in the MAYHEM shaping room.

This is the board I rode in Brazil this year and it was so good that I wanted the same board, so I brought it back to LOST.

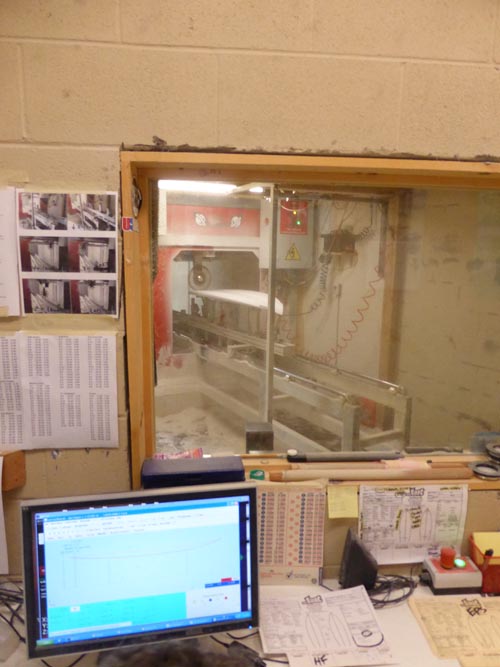

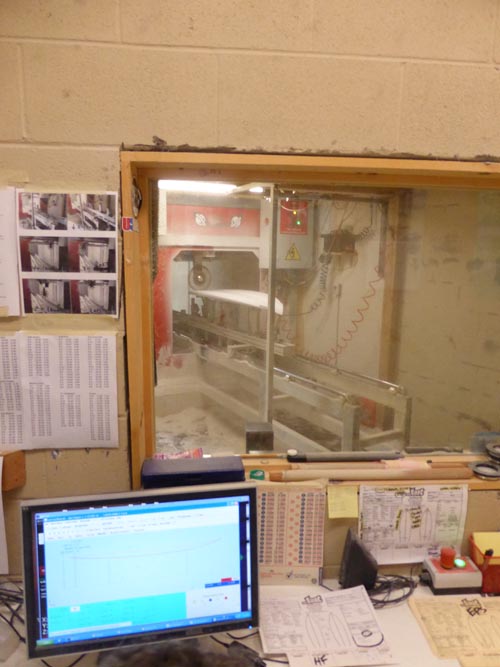

This is the AKU machine as seen from the control room.

Cutting blanks. It takes about 20 minutes for POLY to cut one board,

Since the blanks of XTR and EPS tend to melt easily due to the heat produced when cutting, it takes about 30 minutes to change the blade (rounded teeth).

Mayhem immediately began shaping the cut blanks.

It seemed like he had come up with a new design for this board, and he was concentrating very hard on shaping it.

I'm looking forward to seeing what kind of board it will be!

MAYHEM has just completed the shape of the stockboard for the "LAYZ POTATO" model "XTR FX".

He showed us the blanks that were about to be transported to the XTR factory to be vacuum glassed into "XTR FX".

MAYHEM has just completed the shape of the stockboard for the "LAYZ POTATO" model "XTR FX".

He showed us the blanks that were about to be transported to the XTR factory to be vacuum glassed into "XTR FX".

As you can see when you look at the ``XTR FX,'' the production process is very time-consuming, with wooden stringers made from special, extremely thin maple wood dyed black, square carbon attached to the rails, and glassed in a vacuum bag.As a result, it is difficult to mass-produce like a POLY board, making it a rare, high-end board.

As you can see when you look at the ``XTR FX,'' the production process is very time-consuming, with wooden stringers made from special, extremely thin maple wood dyed black, square carbon attached to the rails, and glassed in a vacuum bag.As a result, it is difficult to mass-produce like a POLY board, making it a rare, high-end board.

This is MAYHEM watching Chris Ward and the WCT LIVE in Europe.

Rooting for Carissa Moore's heat on a LOST Mayhem board.

This is MAYHEM watching Chris Ward and the WCT LIVE in Europe.

Rooting for Carissa Moore's heat on a LOST Mayhem board.

Behind the desk is the board that Kolohe and Mick used.

Behind the desk is the board that Kolohe and Mick used.

Ward saw Mick's SUB-DRIVER board and said, "This looks good."

He said he'll peel off the sticker and try riding it tomorrow.

Ward saw Mick's SUB-DRIVER board and said, "This looks good."

He said he'll peel off the sticker and try riding it tomorrow.

I started working again, designing surfboard orders using AKU software on my beloved Air Mac.

This is Mayhem. He was happy that there were a lot of custom orders for the "BEACH BUGGY" model after Taj won the WCT last week.

I started working again, designing surfboard orders using AKU software on my beloved Air Mac.

This is Mayhem. He was happy that there were a lot of custom orders for the "BEACH BUGGY" model after Taj won the WCT last week.

Luvsurf is currently holding a sale to celebrate the "BEACH BUGGY" victory, so please take advantage of this as well .

Luvsurf is currently holding a sale to celebrate the "BEACH BUGGY" victory, so please take advantage of this as well .

This is Mick's SUB-DRIVER board leaning against the wall in the MAYHEM shaping room.

This is the board I rode in Brazil this year and it was so good that I wanted the same board, so I brought it back to LOST.

This is Mick's SUB-DRIVER board leaning against the wall in the MAYHEM shaping room.

This is the board I rode in Brazil this year and it was so good that I wanted the same board, so I brought it back to LOST.

This is the AKU machine as seen from the control room.

This is the AKU machine as seen from the control room.

Cutting blanks. It takes about 20 minutes for POLY to cut one board,

Since the blanks of XTR and EPS tend to melt easily due to the heat produced when cutting, it takes about 30 minutes to change the blade (rounded teeth).

Cutting blanks. It takes about 20 minutes for POLY to cut one board,

Since the blanks of XTR and EPS tend to melt easily due to the heat produced when cutting, it takes about 30 minutes to change the blade (rounded teeth).

Mayhem immediately began shaping the cut blanks.

Mayhem immediately began shaping the cut blanks.

It seemed like he had come up with a new design for this board, and he was concentrating very hard on shaping it.

I'm looking forward to seeing what kind of board it will be!

It seemed like he had come up with a new design for this board, and he was concentrating very hard on shaping it.

I'm looking forward to seeing what kind of board it will be!